223 Bright Alkaline Cyanide-Free Zinc Plating Process

2017-12-05

Code:223

Name:223 Bright Alkaline Cyanide-Free Zinc Plating Process

1. The additives are in two packages parts, the coating brightness and throwing power can be independently controlled, meeting the requirements of different plating pieces.

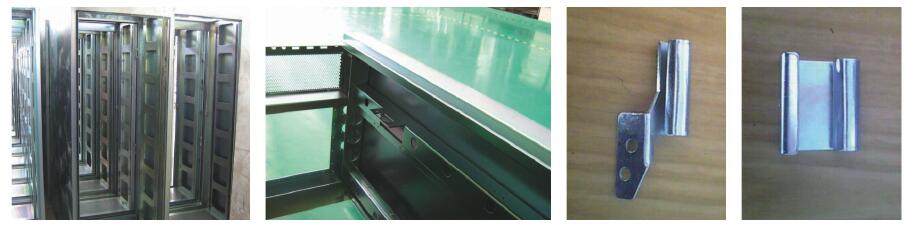

2. Exhibits mirror bright, similar to bright acid Zinc plating.

3. Highly ductile, the 20um thick deposits can be on free bending. No blister is produced when immediately immersing in cold water after thermal shock at 200℃ for 60 minutes.

4. Tolerant at high temperature, it still produces mirror bright deposits even from 50℃ bath.

5. Stronger covering power, better than cyanide Zinc plating.

6. Wide range of usable concentration, which vary from 1 time to 5 times ,the electrolyte still keeps normal.

7. Use pairs of additives ,the throwing power and brightness can be controlled respectively by adjusting the usage of 223A, 223B.

The additive can be used to non-cyanide and cyanide electrolyte, which respectively adjust performance and appearance. Easy maintenance.

8. Wide operating range. By the means of Hull test, 6A panel shows only 0.5cm burnt and 0.2A panel exhibits full brightness.

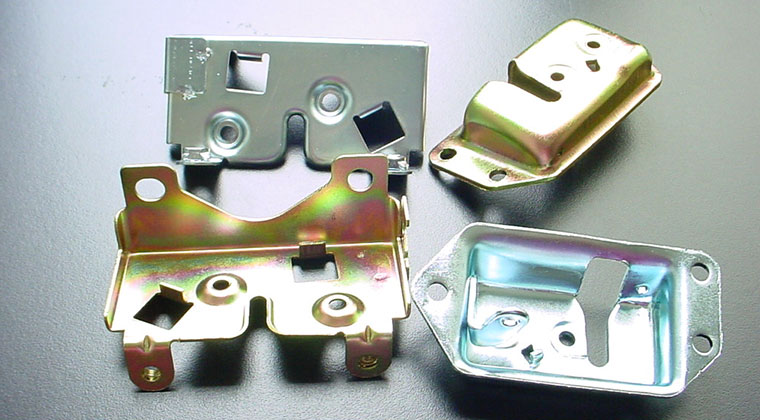

9. Adapted for both barrel plating and rack plating,more adapted for complex workpiece barrel plating.

10. Easy maintenance, non-toxic, easy waste water treatment.

Make-up: 223 A Carrier 8-12ml/L, 223B brightener 1-3ml/L.

Consumption: 223A Carrier 100-200ml/KAH, 223B brightener 50-100ml/KAH.